Batch meters

Liquid batching needs an accurate flow meter with high repeatability so as to ensure high demands of the technology itself by which means it is possible to select batching meters with an induction flow meter or meters with oval gears whereas maximum advantages of individual measurement principles can be utilised. Consequently, this meter can be supplied with the adjusting component for the batch itself, namely also in the industrial version for manipulation using gloves, or with the control electronics for the shut-off valve so that the measured batch can be as accurate as possible and the hundred-per-cent result of the entire system can be provided.

FLOW 38 BATCH Batching meter

It is a comprehensive compact system solving the batching issue from batch adjustment, its measurement, possibly its further handling, up to operation of the actuator using 230VAC control voltage. The operator control is adapted for using gloves when handling so that it is conformable to application in heavy industry.

|

|

|  |  |

FLOW 37 Batching meter

The FLOW 37 compact induction flow meter is designed for exact measurement of various fluids during the batching process, namely their lower amounts with a very high accuracy and repeatability of 0.1%. Possible applications are such as filling bottles, cups and pots with dairy products or with other products intended for sale.

|

|

|

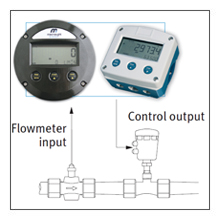

GX 030 Industrial batching unit

The GX030 evaluating control unit is intended for batching cycle control in various variants accommodated to all types of input signals (flow meter types) from REED contact through NAMUR, NPN and PNP pulses, active pulses to 4-20mA or 0-10V. The unit can be battery-operated up to 230VAC. The actuating signal can be again as required, i.e. active, passive, or relay outputs.

|

|

The meter is supplied without display and with 12÷24VDC power supply. In addition, it is equipped with an input signal for optional synchronization of the measuring cycle with the batch start, but it can also serve as a control signal for starting the batch from the parent system. The pulse input can indicate the flow volume in millilitres for instance, or it can be used for valve control as well.